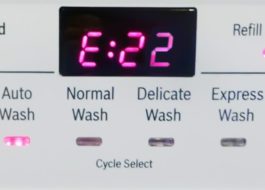

Kaiser washing machine displays error E22

If error E22 appears on the display of your Kaiser washing machine, it is recommended to check the laundry in the drum. Most likely, it is crumpled and threatens the machine with imbalance - it is necessary to straighten things, report or remove some clothes. If after restarting the cycle the code repeats, then the breakdown is more serious: the tachogenerator and control board are suspect. It is better to entrust diagnostics and repair of the control module to a service, but you can check and repair the tachometer yourself. Step-by-step instructions and advice from experienced craftsmen will help.

If error E22 appears on the display of your Kaiser washing machine, it is recommended to check the laundry in the drum. Most likely, it is crumpled and threatens the machine with imbalance - it is necessary to straighten things, report or remove some clothes. If after restarting the cycle the code repeats, then the breakdown is more serious: the tachogenerator and control board are suspect. It is better to entrust diagnostics and repair of the control module to a service, but you can check and repair the tachometer yourself. Step-by-step instructions and advice from experienced craftsmen will help.

Secondary signs of sensor failure

You can suspect incorrect operation of the tachogenerator or speed sensor not only due to error E22. Much more often, a breakdown appears earlier - the “behavior” of the washing machine changes for the worse. As a rule, the “symptoms” relate to the spinning of the drum:

- Kaiser switches gears sharply, accelerates and brakes at lightning speed;

- the acceleration speed of the drum exceeds the specified mark (both set by the user and the maximum number of revolutions of the machine);

- the drum does not spin up to the specified speed or remains completely motionless;

- items are not wrung out or washed at the end of the cycle.

Code E22 means that Kaiser has a problem with the tachogenerator or control board.

Before you can figure out why your Kaiser machine is throwing a code, you need to rule out a technical glitch. It is enough to turn off the machine and restart it after 15-20 minutes. During this time, the system will reset its previous settings and reboot. There was probably a temporary malfunction or an accidental spin shutdown.

If rebooting and resetting error E22 did not help, then you can’t wait any longer. It is necessary to interrupt the running program and begin a comprehensive diagnostic. You should not ignore the breakdown, otherwise the situation will worsen: the engine will burn out or the control board will fail. It’s better not to take risks, but to start repairing right away.

Let's find the element

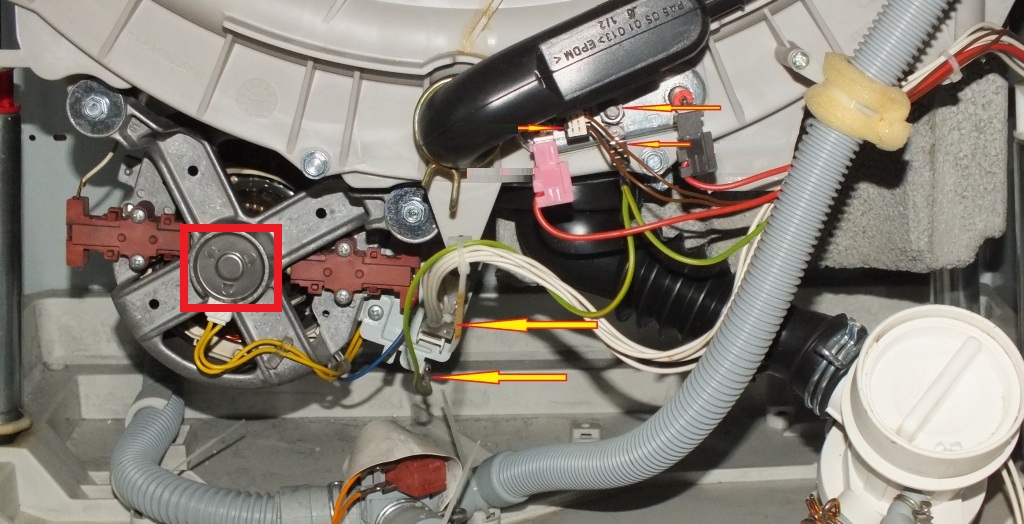

To determine the cause of the failure, you need to check the speed sensor for serviceability. But first you have to find it. There will be no difficulties with the latter: the tachogenerator, regardless of the brand and model of the washing machine, is located in one place - on the motor shaft. All that remains is to get to the engine. The instructions on what to do are as follows:

- disconnect Kaiser from communications;

- remove the back panel of the case;

- tighten the drive belt;

- We find the motor under the washing tub.

Having seen the engine, we pay attention to its shaft. There will be a small metal ring here - a tachogenerator. True, you cannot unhook the sensor at this stage: first you must dismantle the entire motor. Only after removing the engine can you begin diagnostics and find out the causes of the failure. It is worth understanding that do-it-yourself repairs of such key components require some experience. Without knowledge and practice, it is better not to get involved in electronics - there is a high probability of aggravating the situation, even to the point of “fatal outcome” of the equipment.

Testing the part

You can check and repair the motor with your own hands, the main thing is to act strictly according to the instructions. A prerequisite is photographic recording or marking of the “wiring” on the engine. It is important to mark the terminals or photograph their location before disconnecting the wires. This trick will help you avoid mistakes when reassembling the washing machine. Next we proceed to dismantling:

- loosen the screws securing the engine;

- loosen the motor in both directions;

- we pull it sharply towards ourselves, removing it from the grooves.

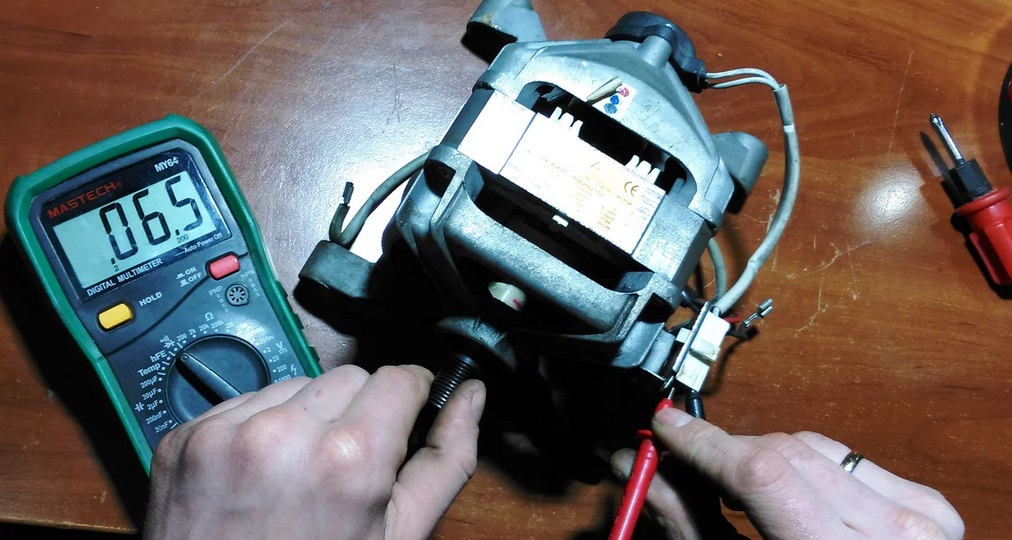

Having removed the engine, we proceed to inspect the sensor. First of all, we check the wires connected to it: whether the contacts have come loose or whether the insulation has been damaged. It is possible that the sudden spinning of the drum affected the electronics - the connection was lost, the tachogenerator stopped working, and error E22 was displayed. In this case, repairs will be limited to stripping the conductors and tightening the terminals. External “order” does not mean that the tachogenerator is working properly. Diagnostics also includes testing the sensor with a multimeter. It is better to check the sensor in two ways:

- through an ohmmeter (when applying probes to the sensor contacts, about 60-70 Ohms should appear);

- through a voltmeter (turn on the “Voltage” mode, apply the probes while accelerating the engine, and look at the display: the norm is 0.2 Volts).

If the values shown by the multimeter do not correspond to the norm, then error E22 is not accidental - the sensor is faulty. The tachogenerator cannot be repaired; you will have to buy a new one and install it instead of the old one. As practice shows, the speed sensor rarely breaks down. More often, chaotic rotation of the drum is caused by failures in the electronics and circuit board. In this case, there is only one way to correct the situation - contact the service for professional help. It is not recommended to check the module yourself, ringing the microcircuits and contacts - there is a high probability of irreversibly breaking the unit.

Interesting:

Reader comments

- Share your opinion - leave a comment

Categories

Washing machine repair

For buyers

For users

Dishwasher

Add a comment